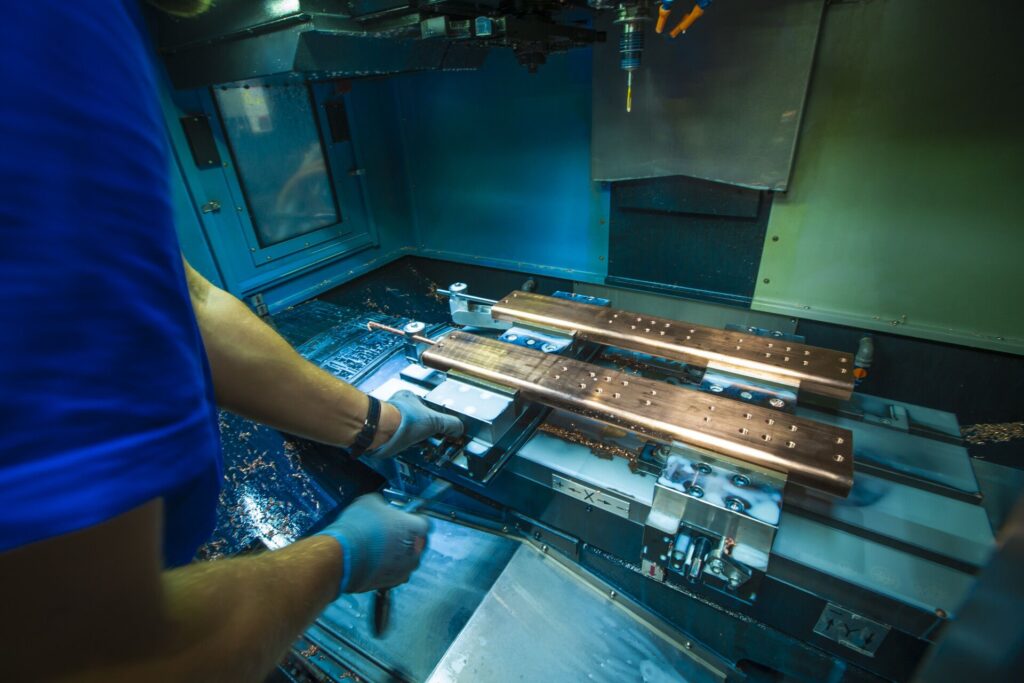

Over the last few years, CNC (Computer Numerical Control) machining has revolutionized modern production practices. Its flexibility, operational efficiency, and precision have all contributed to its rapid popularity and extensive usage across diverse industry applications.

In fact, there are multiple fields that can greatly benefit from using aluminum CNC machining. Let’s find out what these industries are and how they can use this state-of-the-art technique.

Which industries should use CNC machining?

1# Medical industry

The medical industry heavily relies on customized products of high quality that satisfy the various needs of patients. What is more, it also requires a lot of precise parts to keep their facilities stocked with all the essential products.

Aluminum CNC machining can assist the medical field in producing high-quality, precise parts for medical equipment, such as, for example:

- surgical instruments,

- orthopedic implants,

- diagnostic equipment,

- implants,

- medical instruments,

- research equipment,

- electrical elements,

- electronic enclosures for monitoring devices,

- MRI machines.

2# Transportation industry

In the transportation industry, longevity is key. Vehicles need robust, strong components to haul heavy cargo for a long time during long-distance routes. By implementing CNC machining in the manufacturing process, they are able to construct such robust parts as, for example:

- passenger rails and vehicles,

- shipping vessels,

- freight trains.

3# Aerospace industry

In the aerospace field, devices require highly precise tools and parts due to the fact that they may encounter various conditions, such as high speeds, extreme air pressures, or fast air currents. Precision is essential to avoid aircraft damage, and even a small mistake can catch on an air current.

Consequently, with CNC aluminum machining, the aerospace industry can produce various lightweight but highly strong elements with specific designs, from engine components to structural elements of a spacecraft, for example:

- airfoils,

- manifolds,

- bushings,

- electrical connectors,

- landing gear parts.

4# Electronics industry

The electronics industry often requires small, lightweight parts and devices with laser-precise proportions. Accuracy is essential, and CNC milling can empower the field to achieve it.

As a result, by using CNC machining, the electronics field can produce, for example:

- enclosures for electronic devices,

- heat sinks,

- electrical insulation,

- amplifier housing.

5# Marine industry

Finally, the marine industry can also benefit from CNC machining. In this case, numerous watercraft elements require unusual shapes or materials, which can be easily achieved by this technique with minimal effort.

It is also worth mentioning that the marine industry requires high durability and portability, along with water resistance. As a result, components need to be long-lasting, durable, and resistant. CNC milling can assist in creating such parts, according to exact design specifications, such as:

- insulating cases,

- electronic components,

- engine parts,

- prototype molds,

- other boat components.

All in all, aluminum CNC machining can be used in a wide variety of industries. Its superior precision and efficiency make it an indispensable tool in the medical, transportation, aerospace, electronics, marine, and many more industries.