Are you tired of relying on traditional energy sources that are both expensive and harmful to the environment? Look no further than industrial turbines! Not only are they reliable, but they also provide sustainable energy solutions that can significantly reduce your carbon footprint. In this post, we’ll explore the benefits of utilizing industrial turbines for all your energy needs. From cost-effectiveness to environmental sustainability, you’ll discover why more businesses and individuals are turning to this innovative technology as the future of energy production. So buckle up and get ready to learn how these powerful machines can revolutionize the way you consume energy!

What are Industrial Turbines

Industrial turbines are large machines that are used to generate electricity. They work by using the energy of moving water or air to turn a turbine, which in turn activates a generator to produce electricity. Turbines can be either hydropower or wind power.

Hydroelectric turbines are the most common type of industrial turbine. They use the energy of moving water to generate electricity. The water is usually dammed up behind a large reservoir and then released through a narrow channel called a penstock. The moving water turns the blades of the turbine, which activates the generator to produce electricity.

Wind turbines are another type of industrial turbine that uses the energy of moving air to generate electricity. The wind turns the blades of the turbine, which activates the generator to produce electricity. Wind turbines can be either onshore or offshore.

Benefits of Industrial Turbines for Energy Production

Industrial turbines offer a variety of benefits for energy production, including reliability and sustainability. Turbines are able to operate continuously for long periods of time, providing a consistent and reliable source of energy. In addition, turbines can be powered by renewable sources of energy, such as wind or solar power, making them a sustainable option for energy production.

Types of Industrial Turbines

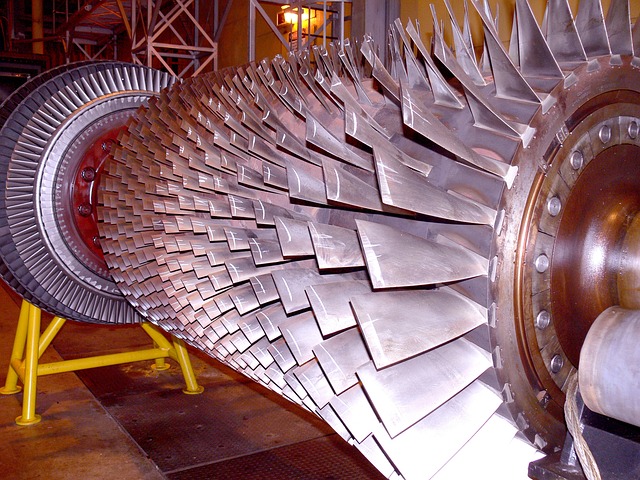

There are three types of industrial turbines commonly used for energy generation: steam, gas, and water. Each type has its own advantages and disadvantages that must be considered when selecting the best option for a particular application.

Steam turbines are the most common type of turbine in use today. They are typically used in power plants to generate electricity. Steam turbines vary in size from small units that can power a single factory to large units that can power an entire city. The main advantage of steam turbines is their efficiency; they can convert a high percentage of the energy in the fuel into usable electricity. The main disadvantage of steam turbines is that they require a constant supply of high-pressure steam, which can be difficult and expensive to maintain.

Gas turbines are less common than steam turbines but are growing in popularity due to their flexibility and lower operating costs. Gas turbines can run on natural gas, propane, or other fuels, making them well suited for applications where a constant supply of high-pressure steam is unavailable. Gas turbines vary in size from small units that can power a single factory to large units that can power an entire city. The main advantage of gas turbines is their flexibility; they can be adapted to run on different types of fuel depending on what is available. The main disadvantage of gas turbines is their lower efficiency compared to steam turbines; they convert less of the energy in the fuel into usable electricity.

Water turbines are the least common type of turbine but have certain advantages over steam and gas turbines. They are typically used in hydroelectric power plants to generate electricity from the energy of moving water. The main advantage of water turbines is their efficiency; they can convert a high percentage of the energy in the moving water into usable electricity. The main disadvantage of water turbines is that they require access to a constantly flowing body of water, which may not be available in some locations.

Cost and Efficiency Considerations

Industrial turbines are a reliable and sustainable option for your energy needs. Here are some cost and efficiency considerations to keep in mind:

-Turbines are more efficient than other forms of energy generation, such as petrol or diesel generators. This means that you’ll save money on fuel costs over time.

-Turbines can be used to generate electricity, heat, or both. This flexibility gives you the ability to tailor your energy use to your specific needs.

-Turbines are typically low maintenance, meaning you won’t have to spend much on upkeep.

-Turbines can last for decades with proper care, so you won’t need to replace them often.

Advantages and Disadvantages of Industrial Turbines

As with any type of energy generation, there are advantages and disadvantages to utilizing industrial turbines. However, when compared to other forms of energy generation, industrial turbines have many more advantages.

The biggest advantage of using industrial turbines is that they are extremely efficient. They can convert up to 90% of the fuel they use into usable energy, which is significantly higher than most other forms of energy generation. This means that less fuel is needed to generate the same amount of power, which reduces emissions and helps to keep costs down.

Another advantage of industrial turbines is that they are very reliable. They are designed to operate continuously for long periods of time with little maintenance required. This makes them ideal for use in applications where uninterrupted power is critical, such as in hospitals or data centers.

While there are certainly many advantages to using industrial turbines, there are also some disadvantages. One downside is that they can be quite loud when operating. This can be a problem in areas where noise pollution is already an issue or if the turbine is located near residential areas. Additionally, because they rely on high winds to function properly, they may not be suitable for all locations.

Environmental Impact of Industrial Turbines

Utilizing industrial turbines for your energy needs comes with a number of benefits, one of which is that it is a more sustainable and environmentally friendly option than other forms of energy generation. Here, we take a look at the impact industrial turbines have on the environment:

When it comes to greenhouse gas emissions, industrial turbines are far cleaner than other forms of energy generation such as coal-fired power plants. In fact, according to the US Environmental Protection Agency, a typical coal plant emits approximately 2,000 pounds of carbon dioxide for every megawatt-hour of electricity produced, while a natural gas-fired turbine emits just 400 to 600 pounds. This means that by switching to an industrial turbine for your energy needs, you could potentially reduce your carbon footprint by up to 80%.

In addition to their lower emissions, industrial turbines also have a smaller land footprint than other forms of energy generation. For example, a single wind turbine can generate enough electricity to power around 500 homes, while taking up just a few acres of land. Compare this to a coal mine which can easily span several thousand acres and you can see why industrial turbines are much more efficient in their use of space.

Another key benefit of using industrial turbines is that they have very little water requirements when compared to other forms of energy generation such as nuclear or hydroelectric power. This is important not only from an environmental standpoint but also from an economic one – using less water.

Conclusion

Industrial turbines are a reliable and sustainable option for meeting energy needs in many industries. By utilizing industrial turbines, businesses can save money on energy costs, reduce their carbon footprint, and help contribute to global sustainability initiatives. Additionally, these systems require little maintenance or upkeep over the years as they have been designed with longevity in mind. As the demand for clean energy continues to grow worldwide, industrial turbine technology is proving to be an excellent choice for helping companies meet their energy needs without sacrificing reliability or environmental protection.