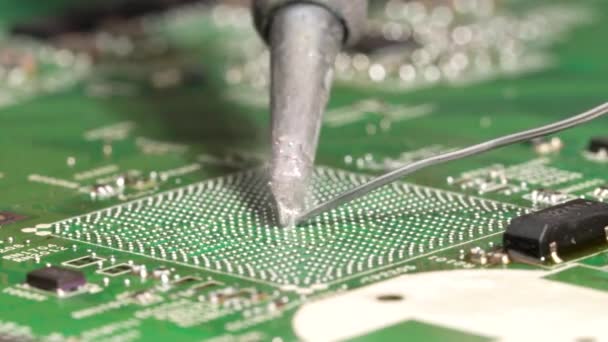

Also known as Ball Grid Array Soldering, BGA soldering is one major alternative to the field of packaging higher input and output devices as per the modern industrial demands. Unlike any of the other packages like the quad pack which uses pins, this one will ensure a grid-like pattern, from where the name came from. This pattern comprises pads with balls of solder. These balls are used for connecting to any PCB or printed circuit board with one matching set of the copper pads. All these components together can help to complete the circuit.

Ways in which BGA gets soldered right into PCB:

Before trying to solder BGA into PCB, there were multiple cons associated of whether soldering the BGA packages can be as reliable as the existing soldering forms. It is mainly because as the pads are located right under the device, they remain hidden during soldering. That will need some strict optimization and adherence of the best and proper method for ball grid array soldering. Even after the basic soldering process gets covered, there needs to be an inspection to be followed and rework in case there remains some imperfections.

- BGA based soldering method has actually improved pretty significantly and to such a point where if the process is set up properly, it can easily surpass reliability of quack plat packs for soldering.

- Mainly because of the higher reliability scale, you will come across BGA assembles in large scale production panels. Manufacturers have to make a lot to match the growing demands of clients and their uses.

- The entire process associated with BGA soldering will utilize one major technique, also called reflow. This process will need reflow oven for melting down the solder balls.

- When the entire BGA assembly gets heated to a certain heat up temperature, the balls for solder under the main component will start to melt.

- The reflow oven, as mostly known in its technical term, will have intricate controlling heat. On the other hand, you have to solder ball, which comprises of precise solder amount within.

- Whenever the oven heats the current assembly, the balls will start to melt. The surface tension of the present molten solder will allow the package to actually remain aligned to given circuit board as the solder starts to cool down.

- For ensuring that the molten solder ball gets to stay separated from the adjacent form of molten balls, the composition is controlled under careful consideration. It works more like the reflow temperature.

- This stage is mainly possible as the solder properties with the specified reflow oven temperament will result in partially molten balls of solder.

Focusing on the soldering task by hand:

BGA soldering mainly comprises two tough parts. One is the rework, which has been mentioned already. Another one is hand soldering. For that, it is mandatory for you to practice to get these tasks done in a satisfactory manner. Be sure to check out how you must solder and then de-solder the BGA based packages by using hand power. The major heating form while desoldering will be hot air. You can consider that method while trying by hand. So, next time you are planning to use hot air for de-soldering BGA package, be sure to focus on the steps as mentioned below.

- You can start the procedure by applying one whopping layer of the liquid flux. Make sure to place that layer on sides of the current BGA package.

- For the next step, you have to preheat the package right from the bottom with the help of the pre-heater. On the top, you will be using hot air for covering the task of hot air based rework system.

- Now, the time has come for you to heat the tip of the package. You can do that with the help of proper BGA nozzle.

- Once the solder balls have melted under the BGA package, you can use a proper tool to pick up right package. Using tweezers or vacuum pick up tools can work best for this stage.

For some more details in this sector, you are asked to get in line with professionals. They will target the process on your behalf and will describe each step before taking.