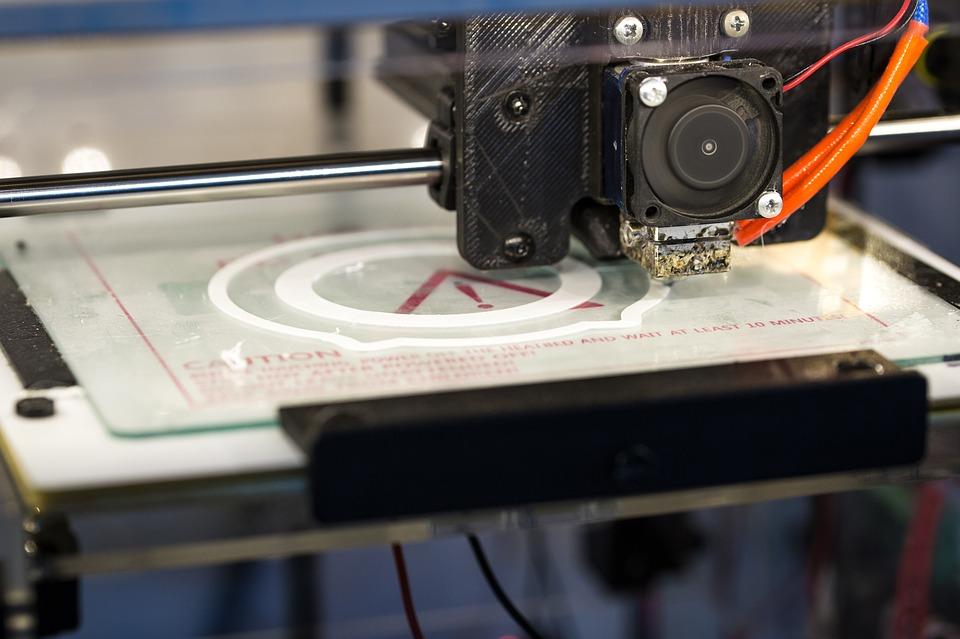

The concept of 3D printing is gaining prominence across the global these days. However, 3D printing technology is not a new invention. In the year 1974, Davis E.H. Jones developed the concept of 3D printing which was implemented and upgraded to better 3D printing technologies by several scientists in the following years. The 3D printing technology is used for creating a three-dimensional tangible object by using Computer-Aided Design (CAD). Unlike the usual paper-based printing devices, 3D printing technology creates an object by adding layer by layer of a particular type of material. A digital file is created with the help of a 3D scanner or a haptic device and it is uploaded in the 3D printer. The command is run and the liquid molecules or powder grains of materials such as metals and plastics are solidified or fused to create an object.

3D Printing Global Market Outlook:

The 3D printing technology ensures a cost-effective, versatile, and highly customized mass production and manufacturing of commodities. The growing demand for 3D printing has enlarged the 3D printing market size in recent years. For the last few years, the global 3D printing market has experienced an exponential growth rate. In the next 5-10 years, the major end-use industries of this technology will be defense, construction, and aerospace. The demand for 3D printing technology is growing at a CAGR of 15-25 percent. In addition to this, there are several industries that are incorporating 3D printing technology in the manufacturing process. Fashion and Energy are such industries and the demand in these sectors are growing at a CAGR of 25-35 percent.

Regions such as North America, Western Europe, and APAC countries like Australia, Hongkong, Singapore, and Japan are the high maturity regions. By 2025, APAC and LATAM regions are expected to contribute significantly towards the growth of the global 3D Printing (3DP) market.

The suppliers’ market for 3DP majorly constitutes of 4 types of divisions, i.e. 3D printer manufacturers, 3D printer manufacturing and service providers, only service providers, and 3D design and modeling service providers. 3D printer manufacturers do not offer printing services and they limit their activities to supply and maintenance of 3D printers. On the other hand, 3D manufacturing and service providers offer maintenance, printing services, and 3D systems. Likewise, printing services are only provided by service providers. Lastly, the design companies offer tools, packages, software, and services for designing and developing the CAD files and for creating 3D models as well.

Major Developments in 3DP Technology in the Past Decade

The modern 3D printing technology is widely used by a myriad of industries such as construction, defense, aerospace, and medical and healthcare. In the medical and healthcare industry, prosthetics and implants are the primary drivers of demand for 3DP technology. In fact, the technology is expected to excel in bio-printing by the year 2020. The 3D printers are also used in limited quantities for rapid prototyping and direct manufacturing of parts in industrial sectors such as medical devices and consumer electronics. Moreover, the 3D printers are also used to print the functional objects that are used for presentation models and pattern making on casting.

The high versatility of 3DP technology and its assistance in mass customization is possible due to the following developments in the technology:

- Fused Deposition Modeling (FDM): It is a method of rapid prototyping in which the materials such as plastic or a conductive metal is melted and extruded out of a nozzle. Simultaneously, the molten material is layered in the sequence as determined by CAD. It is one of the least expensive 3DP technologies available in the market and is mainly used for preparing presentation models and pattern making.

- Stereolithography (SLA): This is the first 3DP technology ever known to people and was invented by Charles Hull in 1986. It is the most commonly used 3DP technology by the industries. This technology uses liquid polymer resin, which is cured and hardened by ultraviolet light, and UV laser to build the object layer by layer.

- Selective Laser Sintering (SLS): Also known as powder bed fusion, this technology is the most expensive 3DP technology. It uses a high power laser to fuse the small particles of materials such as glass powder, ceramic powder, and plastics. The desired structure of the three-dimensional object is obtained as per the CAD. The material powder is selectively fused with each other in the form of layers on the surface of a power bed.

3D printing technology has ushered a new revolution in the printing industries across the globe. The technology is being widely used in various manufacturing industries due to the major innovation that has taken place in 3DP technology. In the next 5-10 years, the global market for 3D printers is expected to grow at an exponential rate. Moreover, healthcare and aviation industries are expected to be its major growth driving force.

3D Printer featured image by Lutz Peter from Pixabay.