As a device, the rotary union enables the transfer of media from the stationary source to the rotating source without any kind of cross contamination or leakage. This device permits with movement of fluid media like oil, water and coolant from the stationary device like sink, oil tank and vat to a moving device which are like engine, propeller and turbine. The process is made possible by securing the input valve to the stationary media source being attached to the rotating machine to the outlet valve. This valve rotates concurrently with the machine while operating. The process provides with a constant fluid transfer that if being operated within its appropriate use is going to give years of uninterrupted media transferring service.

What is the role?

The rotary union can also be referred to as a rotation union, rotary joint, swivel union or swivel joint depending on the type of environment that the device required. They do function the same way but have taken on different names over time and through translation around the world. The fiber optic rotary joint present in the rotary union is one of the significant products. Its role is to permit with transfer of the Ethernet protocol through a rotating interface. Its design is quite innovative design is going to meet challenges of matching impedance which controls cross talk and manages losses. There are offered with combinations of data and power in multiple mechanical configurations to meet the applications and needs.

Advantages

- Pre-configured for Ethernet and HD transmission.

- RJ45 connector for direct plug and play standard M12 and other options available upon request.

- High performance contact technology.

- Available with multiple Ethernet channel, power and signal combination. The Ethernet and high definition objective is the Ethernet slip ring.

The rotary union and its design

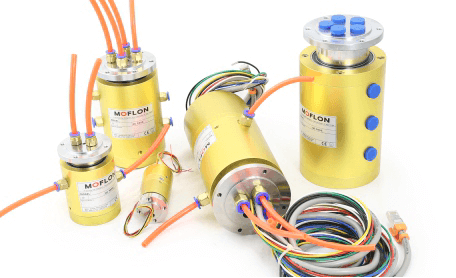

These unions holding the Ethernet slip ring comes in different shapes, sizes and configuration depending on the types of its uses that have in common the shaft and housing unit. These shafts compose of components which carries the media through the rotary union to its final destination. These housing units are the components which keep the rotary union and the media transfer intact. There are a lot of other components which can be common in its composition of rotary unions are that of seals, bearings, retaining rings and O rings depending on how complex the media the types of environment the rotary union will be used in.

With its complexity and size of the device that the rotary union being used for they can be made with more than one passage to provide multiple types of media transfer within in a single device. These types of rotary unions can be handled properly with various pressure and rotational speeds but would typically take on a lower number for each category to factor in for the added passages.

The slip rings perform the same for electrical power and signal the rotary union for the fluid media. These are often integrated into the rotary union to send power and data to and from the rotating machinery within a single device. This kind of all encompassing media based transfer system is getting a common practice in every industry and is also offering with single assembly for this kind of product rotary systems being setting the standard for the functionality of this complex device.

Specificity in the rotary union

With some basic to select the right rotary unions from the rotary union manufacturers there need to check on some specific applications with proper physical dimensions. These are what being looked on with the operating of the device, speed of the device being measured and the speed at which they are rotating. The pressure is also an important factor based on which the media will travel through the device. While considering these specific criteria please refer to the part by part breakdown below for selecting the best possible rotary union for your application.

What makes it important?

The first thing to think about is the measurement considerations for the rotary union. The sort of restrictions if any present and there with the design of the rotary union. The consideration also includes thread types and passage size. The material consideration is going to play a major role in certain applications as well. Typically these rotary unions are made up of black carbon steel or the stainless steel. But with most of the metals can be used for the device. These types of media also need to be addressed early on and the media are transferred through the rotary union. This plays a perfect role in certain application. The standard rotary union lines moves from single passage to twelve passages and the custom designs can go up to any number of passages that are needed.

The conventional rotary designs

The spring loaded seal is used to keep the fluids or gas medium from being dispersed into the atmosphere. There are springs used in the rotary joint to maintain in initial seating and the rotary joint which is pressed sealed once in operation. The low pressure of the vacuum service relies on the spring force to create the seal. Even the conventional rotary joints are either self supported with the use of an internal carbon guide or external supported using the rods or a mountain bracket. These are designed to accommodate with a wide variety of media conditions including very high and low temperatures, flows and pressure which include vacuum applications. These are unlike other fluid transfer mechanisms, rotary unions works for applications involving any combinations of rotation angles including the continuous rotation in one direction. These function by connecting a stationary input or supply to a rotating part that permits with moving connection to be preserved and permitted to the flow of media. These are mostly into use across industries in the form of compact rotary unions for semiconductor applications to large and rugged duty rotary unions for energy, defense and even for industrial applications.